This block counts the number of degrees (one full rotation is 360 degrees) or full rotations that your motor turns. Through data wires, this block can send out the current number of degrees or rotations, and a logic signal (true/false) based on whether the number of degrees or rotations falls above or below a trigger point.

A trigger point is the specific value in a range of numbers where a change in condition occurs. For example, you might program your robot to stop when the number of rotations passes 10. The trigger point would be 10 rotations.

Specify the trigger point by typing a number into the input box. To specify the range (above or below the trigger point) that will generate the "true" signal, use the pull-down menu to choose greater than or less than [the trigger point].

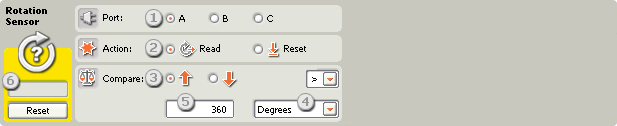

The default setting for the Rotation Sensor block is for degrees more than 360 to generate a "true" signal.

The feedback box will count how many degrees or rotations your motors turn. As a default, the box is set to display degrees. With the Duration property set to Rotation, the current count will be displayed in full rotations. Press the reset button to return it to zero. (To receive feedback, make sure that the motor is connected to the chosen port and that communication has been established with the NXT.)

Data Wires

For the Rotation Sensor block to function, you must drag a data wire from the block’s data hub and attach it to another block’s data hub. You can drag two kinds of data wires from the Rotation Sensor block’s data hub: a logic data wire that will send out true/false signals, and a number (#) data wire that will send out the current number of rotations or degrees. The trigger point can also be supplied dynamically by connecting input data wires from other blocks. (See the Data Hub section below for more information.)

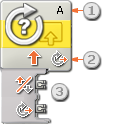

Display Settings

- This letter shows which port the Rotation Sensor block will be monitoring. You can change to another port in the configuration panel if you need to.

- This icon will show whether the block is counting the number of rotations (the solid circular arrow) or degrees (the dashed circular arrow).

- The block’s data hub will open automatically allowing you to drag out a logic (true/false) data wire or a number (#) data wire that will transmit the Rotation Sensor’s current count.

Configuring the Rotation Sensor Block

- Choose which port you would like the block to monitor (A, B, or C).

- Choose either to read a rotation sensor's current value or to reset a sensor's value back to zero.

Set the direction you want to monitor using the radio buttons: forwards or backwards.

Important: Make sure that you choose the right direction or the block may never be able to count to your set trigger value.

- Use the pull-down menu to set whether the block should count the number of rotations or degrees.

- Type the trigger value into the input box and use the pull-down menu to specify whether you want the "true" region to be greater than or less than the trigger value.

The feedback box will show the current count in full rotations or degrees. Push the reset button to clear the count and start from zero.

The feedback value will be displayed in black-colored text for rotations or degrees in the forward (positive) direction; it will be in red-colored text rotations or degrees in the backward (negative) direction.

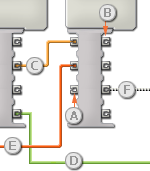

Configuring the Rotation Sensor block’s Data Hub

You can control the Rotation Sensor block dynamically by connecting data wires (from other blocks’ data hubs) to the Rotation Sensor block’s data hub.

Open a block’s data hub by clicking the tab at the lower left edge of the block after it has been placed on the work area.

Data wires carrying input information to a block are connected to the plugs on the left side of its data hub. Data wires carrying output information are connected to the plugs on the right side.

[A] Input plug

[B] Output plug

[C] Number data wire (yellow)

[D] Logic data wire (green)

[E] Text data wire (orange)

[F] Broken data wire (gray)

Passing data from the input plug to the output plug

If an input plug has a corresponding output plug (see A above), the input data will pass through from the input plug to the output plug without being changed. In this case, you can only use the output plug if the input plug is connected to an input data wire; connecting an output data wire to such an output plug without a connected input data wire will cause the output data wire to be "broken" (and colored gray).

Data wires carry specific types of data

Each data wire carries a specific type of data between blocks. For example, if a data wire is dragged from a logic plug on a block’s data hub, it can only be connected to a logic plug on another block’s data hub. The chart below shows what kind of data each plug can accept or send out.

Data wire colors

Data wires are identified with specific colors: wires carrying number data are colored yellow, wires carrying logic data are colored green, and wires carrying text data are colored orange.

"Broken" data wires

If you try to connect a data wire to a plug of the wrong data type, the data wire will be broken (and colored gray). You will not be able to download your program if a data wire is broken.

If you click a broken wire you can read why it is broken in the small help window in the lower right corner of the work area.

Data must be within the possible range of the plug

If an input data wire transmits a value outside the possible range of the plug it is connected to, the block will either ignore the value or change it to a value within its range. For plugs that allow just a few input values (example: just 0, 1, or 2), the plug will ignore the input if a value arrives outside its range.

For plugs that accept larger input ranges (example: 0 – 100), the plug will force any input outside its range to fit. For example, if a Move block’s Power plug receives an input value of 150, the block will change the input value to 100 (i.e., a number within the Power plug’s range).

This chart shows the different characteristics of the plugs on the Rotation Sensor block’s data hub:

| Plug | Data Type | Possible Range | What the Values Mean | This Plug is Ignored When... | |

| Port | Number | 1 - 3 | 1 = A, 2 = B, 3 = C | ||

| Trigger Point | Number | 0 - 2147483647 | Value to compare against | ||

| Trigger Point Direction | Logic | True/False | Direction to use in comparison: True = Forwards, False = Backwards |

||

| Greater / Less | Logic | True/False | Logic used in comparison: True = Greater, False = Less |

||

| Reset | Logic | True/False | True = Reset, False = Read |

||

| Yes / No | Logic | True/False | Result of comparison | ||

| Direction | Logic | True/False | True = Forwards, False = Backwards |

||

| Degrees | Number | 0 - 2147483647 | Scaled value read from sensor. |